Continuous ion exchange theory:

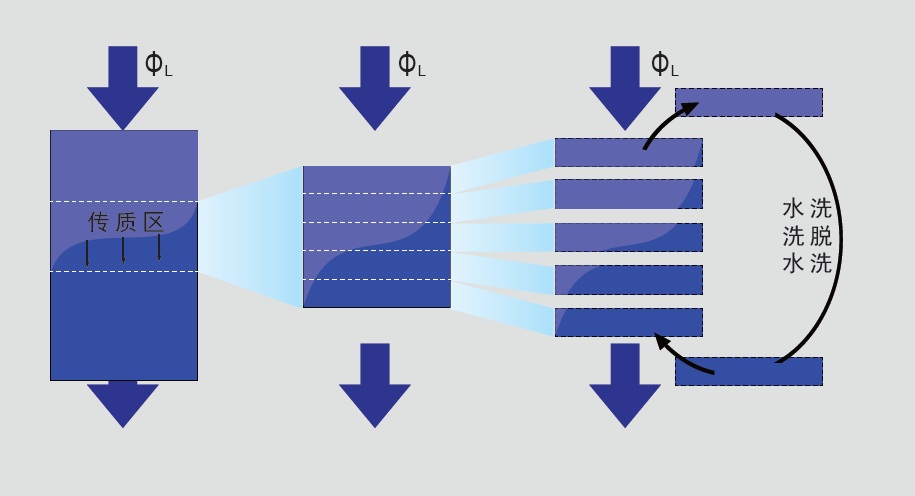

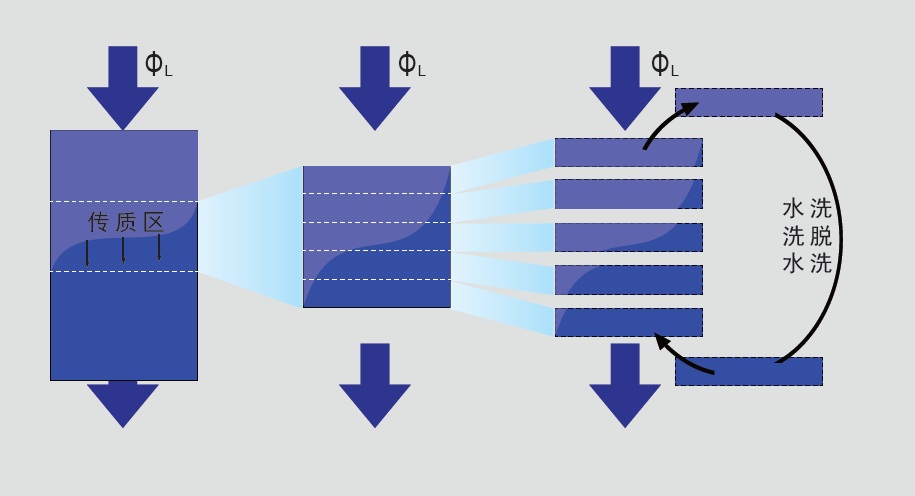

Ion exchange technology, based on the resin functional groups and materials in the adsorption of specific ions is carried out by the exchange process. Ion exchange is a reversible equivalent exchange reaction. Traditional ion exchange is achieved by the application of a fixed bed, which will be divided into three sections, saturation zone, active area (mass transfer area) and fresh resin area. As the exchange progresses, the mass transfer zone continues to move down until the bottom exchange is complete. Only the mass transfer zone is in working condition all through the entire process while saturated area and fresh resin area not. So, the resin utilization rate is low. In order to improve the utilization of the resin, the mass transfer zone is divided into several small units. Once the small units are saturated, they are removed for washing and regeneration. The fresh resin units for processing will return to the bottom of the mass transfer zone for recycling, so as to improve the utilization of resin.

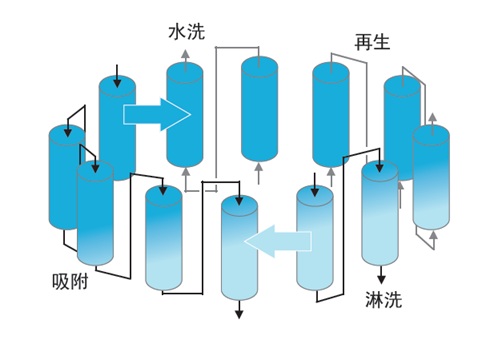

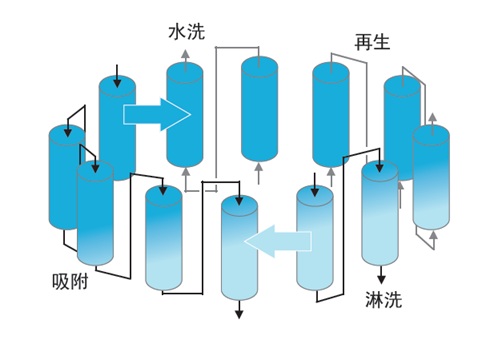

In order to achieve the automatic and efficient operation of the resin unit, we have adopted a new design concept that the resin column small unit are put on a turntable, switch is achieved through the turntable rotation, and the material is distributed through an automatic rotation control. The resin column is divided into exchange, washing, regeneration, rinsing and other functional areas. When the resin unit reaches the specified area to implement the appropriate process, each process can be carried out independently to make the overall process operation continuously.

Advantages of continuous ion exchange:

Advantages of continuous ion exchange:

Integrate all the steps that can run continuously and systemically;

Significantly reduce the use of resin, and make full use of resin;

Extend working life of resin;

Reduce water and chemical consumption as well as operating costs and sewage emissions;

Can remove or separate the material with different characteristics, and can simplify the process;

Maintain the stability of the product composition and concentration in the feed liquid

Can effectively improve the purity and concentration of product liquid, saving the cost of follow-up technology

The use of multi-column system can be flexible to change the production process;

Compact, small area needed, and easy to install in any location;

Fully automated programmed operation control ensures continuous and stable operation of the equipment;

Rotation speed and flow rate can be adjusted.

Continuous ion exchange Typical applications:

Conversion of Sodium gulonate to gulonic acid

Conversion of Vc-Na to Vc

Lysine extraction

Erythromycin extraction

Glutamine extraction

Extraction of colchicine sulfate

Extraction of sodium salt

Glucose is grayed out

Sorbitol

Tryptophan refining

Threonine

Glutamic acid refining

Aspirin Refined

Ribose desalination

Lactate desalination

Citrate desalination

Gulanic acid desalination

Citric acid decolorization

Potassium sulfate production

Potassium nitrate production

Plutonium purification

Nicotinamide recovery

Metal gallium recovery

Recovery of uranium in phosphoric acid

Recycling of waste water

Lithium recovery (rare earth)

Recovery of metal in brine

Recovery of fluoride in waste water

Waste water in addition to zinc

Protein Separation in cheese whey

Removal of copper-vanadium catalyst from adipic acid

Succinic acid to remove copper/alum

Removal of iron from copper electrolytes

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431