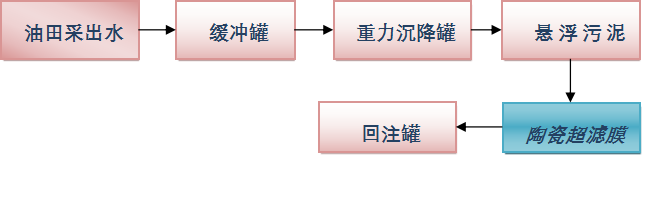

After deep treatment of low permeability oil field, suspended matter in water contains excessive content, and size is unqualified, in response to this problem, three-way membrane based on years of experience in ceramic membrane applications, in processing technology development of filtration system of oilfield produced water treatment, combined with the existing oil field produced water processing treatment, and ceramic ultrafiltration technology, it has simple operation, high degree of automation, no waste oil .

Design flux: 280LMH

Influent water quality index: Petroleum 300-500mg/l, SS 200~300mg/l.

Effluent Water Quality Index: Petroleum ≤3 mg/l , SS≤1 mg/l, grain size ≤1.

(2) Gravity sedimentation - SSF (suspended sludge bed) - Ceramic ultrafiltration membrane process

The original treatment process of oil production in a certain station is: water goes to petrol station → oil tank → primary tank → lifting pump →SSF (suspended sludge bed) → secondary tank → external pump → metal membrane → reinjection (metal membrane is divided into two levels, the first level aperture 10µm, the second level 0.5µm), the treatment process water can not meet the A1 level standard, Heavy metal membrane pollution, frequent cleaning, not long service life. Using 50nm ceramic membrane instead of metal membrane, the effluent water quality reached the A1 level standard.