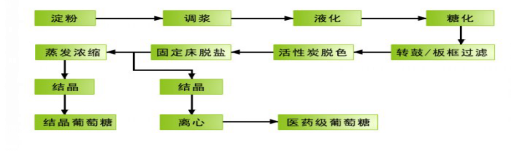

Being also called dextrose, glucose is an essential carbohydrate for human beings, the main source of the required heat energy, the most important basic product in starch industry and the important raw material for medicine, food and related industries. Glucose is produced by enzymatic hydrolysis of starch milk under certain conditions, and in the preparation process of glucose, part of protein, fat, fiber, pigment, salt and other impurities directly affects the quality of glucose, and the traditional process is shown in the following figure:

This traditional glucose production process should add the filter aid in the saccharification liquid drum or plate and frame filtration, and it must adopt the activated carbon as an adsorbent for adsorption bleaching during decolorization, and the process of fixed beds has high regenerant consumption, larger raw material consumption, higher production cost and it is easy to pollute the environment.

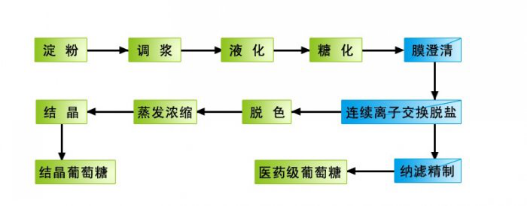

In view of the shortcomings in the traditional process of saccharification liquid treatment, the technology of combining ceramic membrane/coil membrane filtration with continuous ion exchange desalination technology is adopted to reform the production process of glucose. The process flow is shown in the following figure:

Compared with the traditional process, the process not only reduces the production cost, but also achieves the continuous automatic production, and it is a new clean production technology of energy saving and consumption reduction, whose process advantages are as follows:

The ceramic membrane/coil membrane separation technology is used to remove fat, macromolecular protein, fiber, pigment and other impurities in the saccharifying liquid, and the sugar solution is clear and transparent after membrane filtration, and the transmittance of filtrate reaches above 97%, which saves the decolorization process of activated carbon in the traditional process and reduces the amount of front-end filter aid greatly, thereby saving the production cost;

The continuous ion exchange technology is used to replace the traditional fixed bed process, which can save more than 70% of resin, more than 40% of dosage of regenerants and more than 60% of dosage of washing water, thereby greatly reducing the production cost and the environmental pressure of waste water;

Nanofiltration separation technology is used to replace the traditional crystallization centrifugal process to prepare pharmaceutical-grade glucose, whose product purity is as high as 99.5% and whose product quality is stable.

Contact:

Tel:+86 592 6514970

Email:market@guochukeji.com

Skype:18060902001

WhatsApp:18060902001

WeChat:18060902001

TM: guochukeji

QQ:1641011431