Nowadays, the main products of the dairy industry are liquid milk, yoghurt, milk powder, and cheese. In order to meet the rising demand and quality requirements of consumers for dairy products, new membrane separation technologies are increasingly employed to transform the traditional production methods of dairy products. The adoption of new membrane separation technology in the dairy industry can simplify the production process, improve the quality of dairy products, enhance the overall utilisation, lower energy consumption and reduce wastewater discharge.

Guochu Technology Ltd. has imported leading membrane technology and developed a series of new membrane separation technologies that are suitable for the dairy industry:

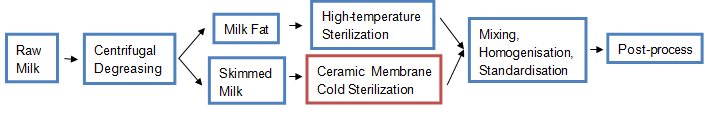

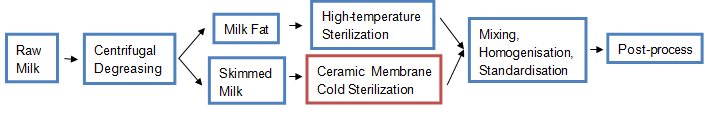

Application of Milk Sterilisation

During heat sterilisation of milk, whey protein is altered, which affects the nutrition of the milk. The use of ceramic membranes for cold sterilisation ensures that the nutrient components of milk are not destroyed while still achieving the desired sterilisation.

The General Process is as Follows:

Skim Milk Concentrate Desalination

Skim Milk Concentrate Desalination

After pasteurisation, centrifugally degrease the fresh milk. Next, cool it down, then finally it goes to nanofiltration for concentration and desalination. During the desalination process, pure water is continuously injected to elute the inorganic salts in the skimmed milk. When desalination reaches a certain level, the nanofiltration concentrate, i.e. the desalted milk, starts the subsequent process for concentration and drying, and the filtrate of the nanofiltration begins the reverse osmosis process to recycle the wastewater. After the wastewater is processed, pure water will be obtained, and it can be used in the nanofiltration process unit for elution by refilling.

Separation of Casein and Whey Protein

Separation of Casein and Whey Protein

According to the molecular weight and micelle size of casein in skimmed milk, the size of the micelle and molecular weight of whey protein and the molecular weight of other components (other proteins, lactose, organic acids and inorganic salts), select the appropriate ceramic membrane microfiltration technology to separate casein egg white and whey protein.

The General Process is as Follows:

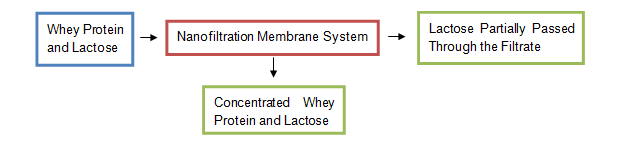

Nanofiltration Concentration of Whey Protein

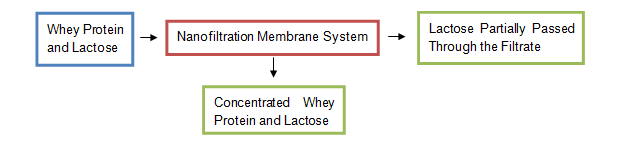

Nanofiltration Concentration of Whey Protein

Nanofiltration membrane concentration and desalination: A hygienic nanofiltration membrane is used to concentrate and desalt the filtrate obtained by filtering the ceramic membrane. Two objectives can be achieved through by this: firstly, the whey protein solution obtained from ceramic membrane is enriched in the nanofiltration concentrate. Secondly, monovalent salts such as Na and K can penetrate the nanofiltration membrane to achieve partial desalination. The nanofiltration filtrate will be water with monovalent salts and a small amount of non-protein nitrogen.

The General Process is as Follows:

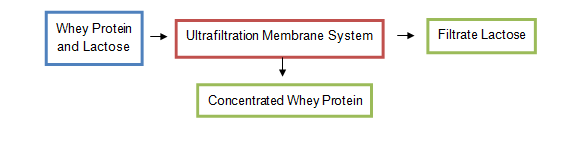

Whey Protein and Lactose Separation

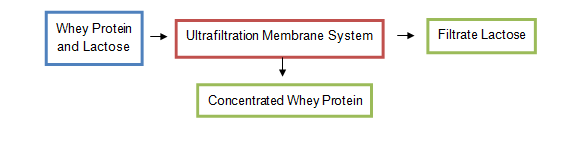

Whey Protein and Lactose Separation

Ultrafiltration membrane filtration: the permeate of nanofiltration enters the spiral-wound ultrafiltration membrane system for further separation and filtration to achieve three purposes: one, to further concentrate the permeate, increase the feed density of electrodialysis, raise the efficiency of desalination, reduce the cost of the electrodialysis process, and meanwhile ensure the concentration of whey liquid after electrodialysis desalination. Two, separate the excess lactose in the whey liquid according to different requirements of whey powder. Three, to remove parts of the ash above divalent, lower the pressure of electrodialysis desalination in the post process and reduce the input of the desalination process.

The General Process is as Follows:

Whey Protein Electrodialysis Desalination

Whey Protein Electrodialysis Desalination

Electrodialysis desalination: An electrodialysis system is used to perform deep desalination of the standardized whey liquid, which can be adjusted according to the final product requirements in the post-process to produce different levels of whey protein.

The General Process is as Follows:

Guochu Technology (Xiamen) Ltd.

Guochu Technology (Xiamen) Ltd. is a high-tech enterprise with membrane separation technology at its core, dedicated to the promotion of new separation technology. With valuable experience in the application of special membranes in the pharmaceutical, chemical, food, beverage, petroleum, petrochemical, nuclear energy and other industries, Guochu Technology has the ability to research and develop membrane products and types of equipment according to the needs of its customers.